Luminaire design plays a key role in maintaining the required performance of a lighting installation.

Thermal simulations and laboratory tests performed according to standard IEC-60598-1 on luminaires have enabled Reggiani to create passive heat sinks in aluminium, units that ensure perfectly efficient, long-lasting LEDs under the standard operating conditions.

This profound understanding of the relationship between luminaire design and thermal performance, combined with over seven years of developing high output LED products, has enabled us to design and test evermore imaginative uses of LED technology.

This ability to correctly design a heat sink and effectively manage heat dissipation throughout the luminaire is demonstrated by a remarkably low failure rate, compared to industry norms.

The in-house laboratory

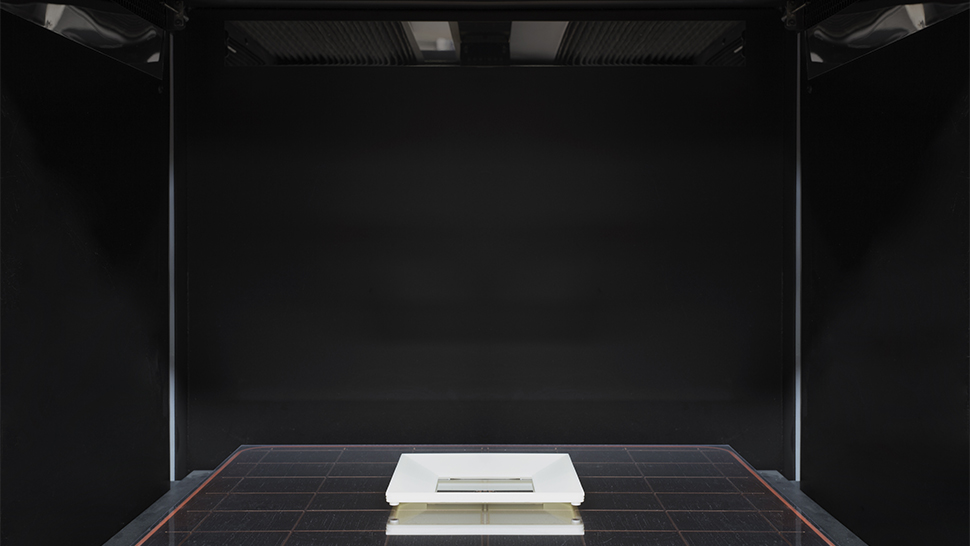

Reggiani Lighting has an in-house laboratory which allows to perform internal tests for the products included in the catalogue.

The range of equipment at the laboratory includes a full size calibrated goniophotometer, a significant investment in optical control that enables extremely accurate photometric readings.

Also housed within the laboratory suite are two integrating spheres and a spectrophotometer. The spectrophotometer allows us to accurately measure the full range of visible light emitted from light sources mounted within luminaires and check the results against manufacturers’ data for a particular batch of LED light sources. In charting this data we are able to improve our understanding of possible changes in spectral output over life.

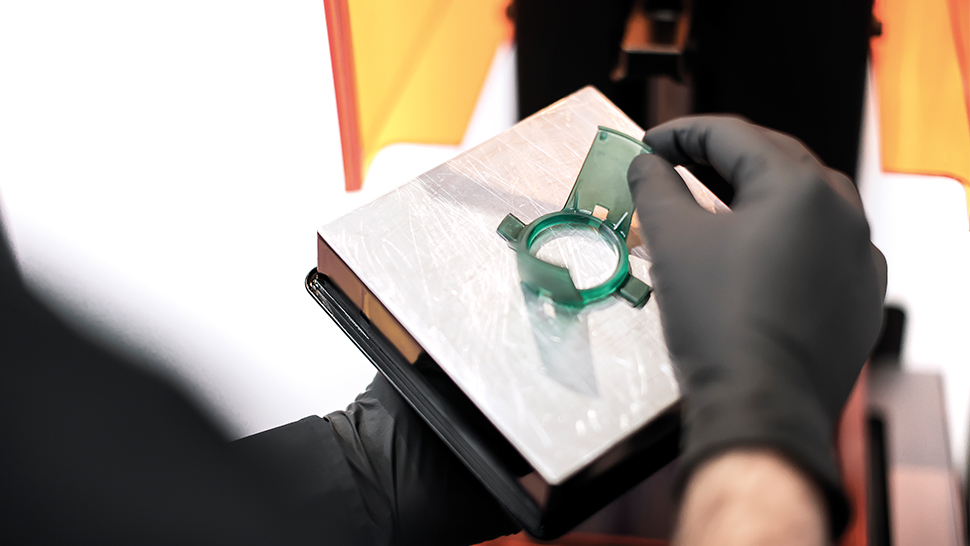

Together with the in-house 3D prototyping and IK/IP testing, this range of tools allow us to evaluate and test standard and customized solutions quickly and effectively.